Struggling with project weight calculations? Using the wrong material density can cause costly errors in shipping and structural planning, throwing your entire budget off track.

The density of stainless steel varies depending on its specific grade. For example, the common 304 grade has a density of about 8.0 g/cm³ (or 0.289 lb/in³). Different alloying elements[^1] change this value, so checking the grade is crucial for accurate calculations.

I often get questions from clients about material weight. It's one of the most practical details in any project, from ordering to logistics. The foundation for getting this right is understanding density. It's not just a number in a textbook; it's a critical property that affects how we handle, ship, and install stainless steel. So, let's dive into the specifics and make this simple.

What Is the Density of Stainless Steel, and What Are the Typical Values by Grade?

Worried that all stainless steel grades[^2] have the same weight? This assumption can lead to unexpected overages in material costs and shipping fees on large orders.

The density of stainless steel is not a single value. It changes based on the grade's specific chemical composition. For example, austenitic grades[^3] (300 series) are generally denser than ferritic grades[^4] (400 series) because they contain heavier elements like nickel.

In my work, I deal with many different grades of stainless steel every day. Each one is designed for a specific purpose, and its physical properties, including density, reflect that. Density is simply the mass of the material per unit of volume. It's an inherent property. I remember a project where a client assumed all stainless steel was the same. They calculated their order based on the density of a 400-series grade but actually needed 316L for its corrosion resistance. The weight difference per sheet was small, but on a 20-ton order, it added up to a significant miscalculation in shipping costs. This is why knowing the specific density for your chosen grade is so important for accurate planning.

Typical Density Values for Common Grades

Here is a table to help you find the approximate density for some of the most common stainless steel grades[^2] we work with.

| Grade | Density (g/cm³) | Density (kg/m³) | Density (lb/in³) |

|---|---|---|---|

| 201 | 7.86 | 7860 | 0.284 |

| 304 / 304L | 8.00 | 8000 | 0.289 |

| 316 / 316L | 8.00 | 8000 | 0.289 |

| 409 | 7.80 | 7800 | 0.282 |

| 430 | 7.75 | 7750 | 0.280 |

| 439 | 7.72 | 7720 | 0.279 |

As you can see, the differences might seem small, but they become very important when dealing with large quantities.

How Do You Calculate Stainless Steel Weight in Practice?

Unsure how to turn a density value into a practical weight for your order? A wrong calculation can lead to ordering too much or too little material, disrupting your project.

To calculate the weight of a stainless steel sheet, you multiply its volume by its density. First, calculate the volume (Length × Width × Thickness), ensuring all units are consistent. Then, multiply that volume by the specific density of your chosen grade.

Let's walk through a real-world example. This is a calculation I do almost daily to prepare quotes for my clients. The formula is simple, but the key is to be careful with your units. The basic formula is:

Weight = Volume × Density

For a flat sheet, the volume is found by multiplying its three dimensions:

Volume = Length × Width × Thickness

Step-by-Step Weight Calculation for a Sheet

Let's calculate the weight of a single 304 stainless steel sheet with the following dimensions:

- Length: 2438 mm

- Width: 1219 mm

- Thickness: 1.5 mm

First, I convert all measurements to meters (m) to match the density unit (kg/m³).

- Length = 2.438 m

- Width = 1.219 m

- Thickness = 0.0015 m

Next, I calculate the volume: Volume = 2.438 m × 1.219 m × 0.0015 m = 0.00445 m³

Now, I use the density of 304 stainless steel, which is 8000 kg/m³. Weight = 0.00445 m³ × 8000 kg/m³ = 35.6 kg

So, one sheet weighs approximately 35.6 kilograms. For a large order of 100 sheets, the total weight would be 3,560 kg, or 3.56 metric tons. This is the number we use for shipping quotes and handling plans.

Why Does Stainless Steel Density Vary, and How Does It Impact Applications?

Confused about why stainless steel grades[^2] have different densities? Not understanding this can lead to choosing a material based on the wrong assumptions about its properties.

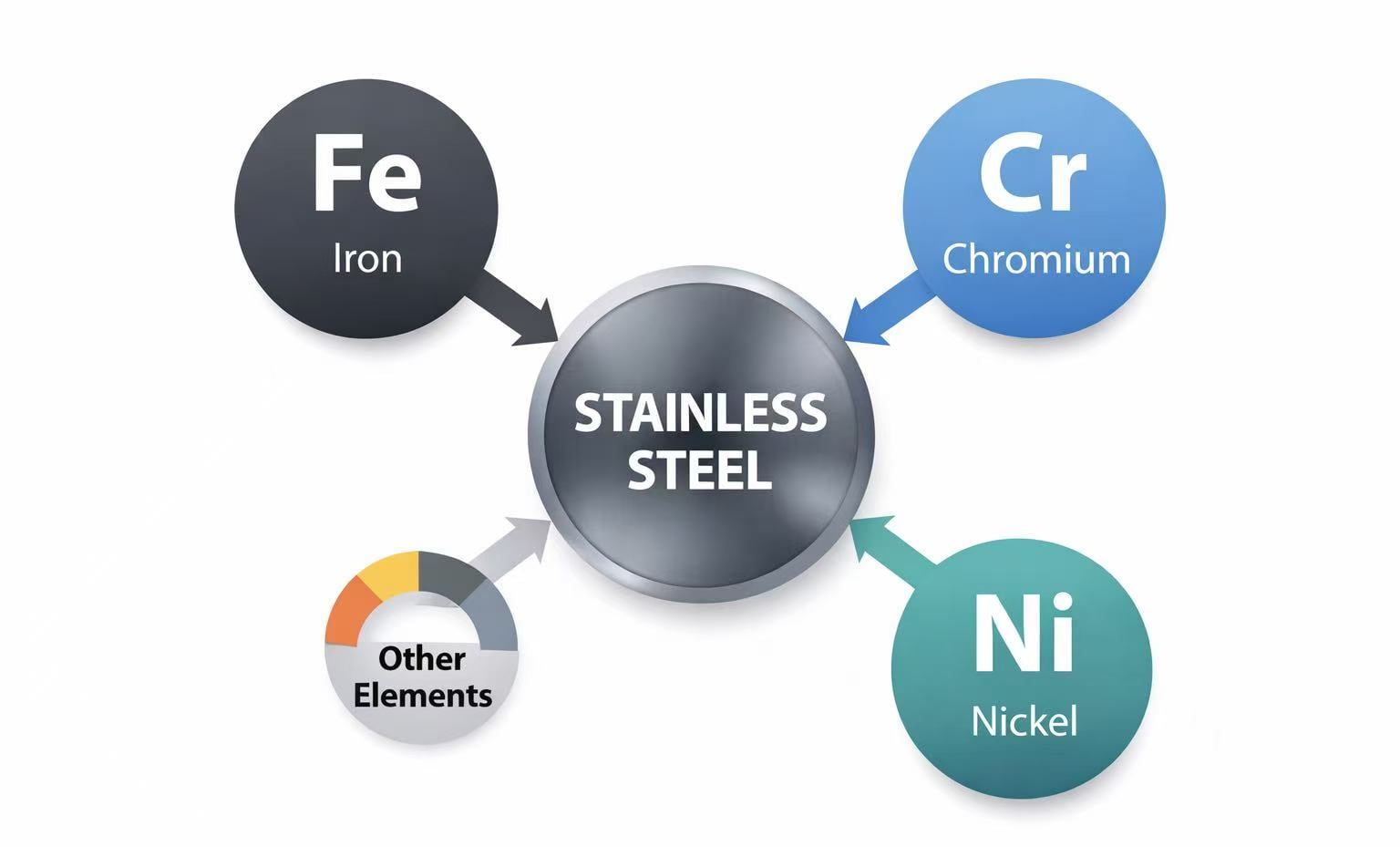

The density of stainless steel varies because of its chemical composition. Different grades contain different amounts of alloying elements[^1] like chromium, nickel, and molybdenum, which have different atomic weights.

This is a very important point I always clarify with my clients. Density is an outcome, not a goal. We don't choose a grade because it has a certain density. We choose a grade for its performance—like the superior corrosion resistance of 316L for marine environments or the formability of 304 for kitchen sinks. The density is just a physical consequence of the specific recipe of elements used to achieve those properties.

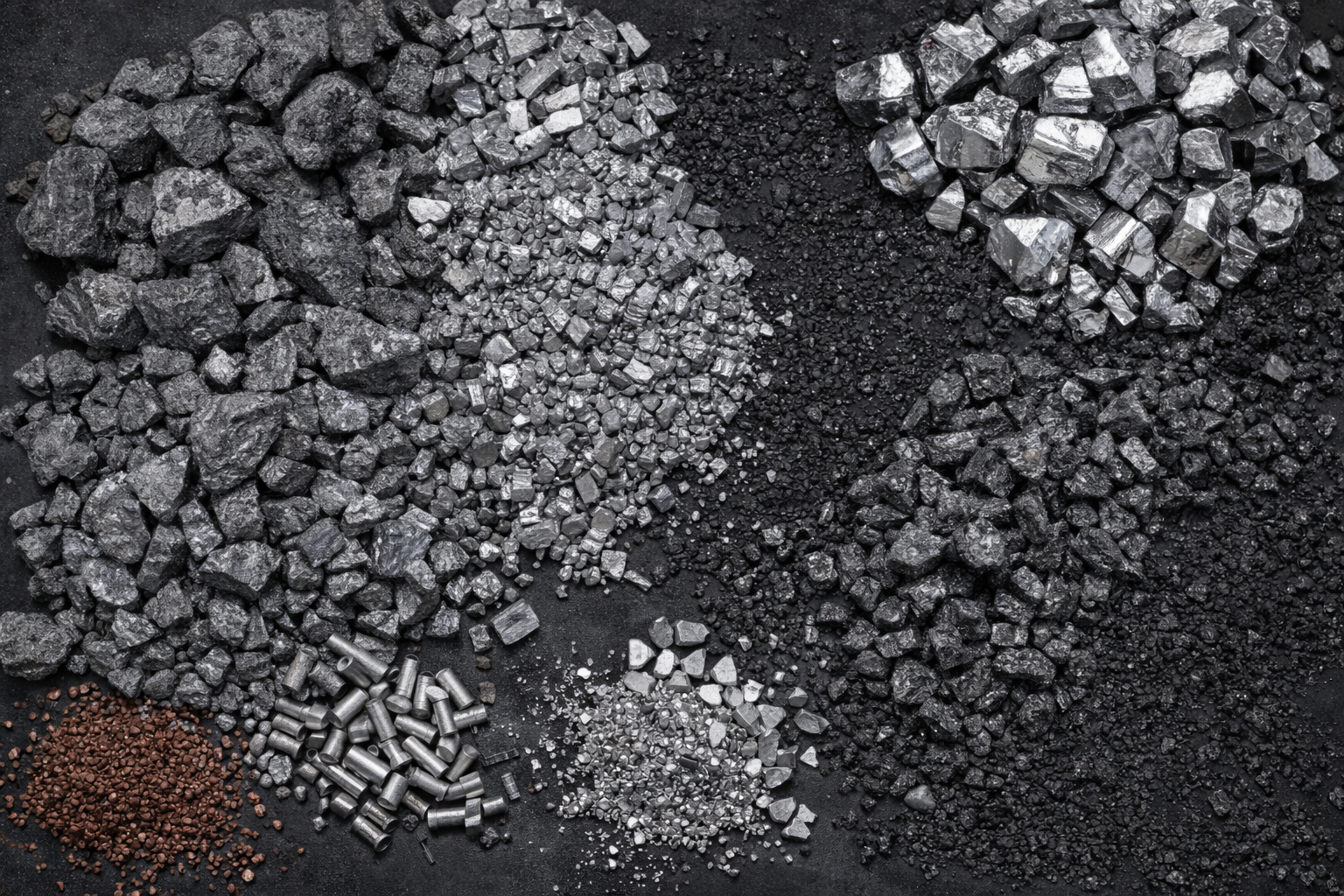

The Role of Alloying Elements

The base element of stainless steel is iron. We then add other elements to give it its "stainless" properties. Each element has its own atomic mass, and adding it to the mix affects the final density.

- Iron (Fe): The main component.

- Chromium (Cr): Essential for corrosion resistance. It's lighter than iron.

- Nickel (Ni): Adds corrosion resistance and makes the steel austenitic (non-magnetic). It is denser than iron.

- Molybdenum (Mo): Increases resistance to pitting corrosion, especially from chlorides. It is also denser than iron.

So, a 300-series grade like 304 or 316 contains a significant amount of nickel. Since nickel is denser than iron, these grades are denser than the 400-series grades, which have very little or no nickel. It's a direct result of the chemical formula. Thinking that higher density means "stronger" or "better" is a common mistake. The strength comes from the alloy's structure and heat treatment, not its weight per volume.

Conclusion

Understanding stainless steel density is essential for accurate project planning. This property is a result of the alloy's composition, not a measure of performance, but getting it right ensures correct calculations.

[^1]: Learn about the key alloying elements that affect the properties and density of stainless steel. [^2]: Explore the various grades of stainless steel to choose the best one for your project needs. [^3]: Learn about austenitic grades and their properties to make informed material choices for your projects. [^4]: Discover the characteristics of ferritic grades to understand their applications and benefits.